avia.wikisort.org - Manufacturer

Prvni brnenska strojirna Velka Bites, a. s.[1] ("First Brno Engineering Plant", known as PBS VB) is a Czech engineering and manufacturing company. It focuses mainly on the development, testing, and production of devices for the aircraft industry.[2] Together with PBS Energo, a.s.;[3] PBS Brno, a.s.[4] and PBS Aerospace Inc.,[5] PBS VB is a member of PBS GROUP, a.s.[6]

This article may have been created or edited in return for undisclosed payments, a violation of Wikipedia's terms of use. It may require cleanup to comply with Wikipedia's content policies, particularly neutral point of view. (May 2020) |

| |

| Type | Joint-stock company |

|---|---|

| Industry | mechanical engineering, aerospace, precision casting |

| Founded | 1950 |

| Headquarters | |

Area served | Worldwide |

Key people | Milan Macholan, CEO |

| Products | Jet engines, Auxiliary power units, Environmental control systems; Precision casting, Cryogenic, Electroplating services |

Number of employees | 800 |

| Parent | PBS Group, a.s. (100%) |

| Website | www |

History

The history of PBS VB has been closely related to the company PBS Brno, originally founded in 1814 by Jan Reiff, who established a textile mill near Brno.[2] As the company was growing, new facilities were built. PBS VB was established in 1950 in Velká Bíteš, Czech Republic to support industrial development of the region.

The first products produced in PBS VB were hammer drills and parts for mining and metallurgical pneumatic tools. In 1951 a production of fittings started.[7]

Modernisation and extension of the production capacities connected with an investment casting hall construction were finished in 1970. At the same time, the company entered the aviation world by developing an auxiliary power unit for Aero L-39 Albatros aircraft.[8]

After gaining experience in the technology of auxiliary power units and environmental control systems, in 2004 PBS VB expanded its product portfolio and included propulsion units – turbojet, turboshaft and turboprop engines for small manned or unmanned aircraft, UAVs and target drones.[9]

PBS VB delivers its products globally and since the 1970s more than 7,000 pieces of turbine equipment for the aerospace industry has been manufactured in PBS VB in total.[10]

Organisation

PBS VB is member of the PBS GROUP composed of:

- PBS Enegro, a.s. active in the power industry

- PBS Brno, a.s. providing services in relation to the construction of power generation and district heating units

- PBS Aerospace Inc., a subsidiary of the PBS GROUP, which is responsible for expanding the business activities in the field of aerospace technology, especially on the American markets

- PBS Velká Bites, a. s. a globally recognised hi-tech manufacturer of power units and other equipment in the field of aerospace

PBS VB has its headquarters in the Czech Republic with other locations in the USA and India.[11]

The company is approved by the European Aviation Safety Agency (EASA)[12] holding the DOA (Design Organization),[13] POA (Production Organization)[14] and MOA (Maintenance Organization)[15] approvals and is ISO 9001[16] and ISO 14001 certified.[17]

Among others, the PBS is a member of the DSIA (Defence and Security Industry Association Czech Republic)[18] and ALV Czech Republic (Association of the Czech Aerospace Industry).[19]

Products and services

PBS VB specialises in design and development of small jet engines for aircraft, UAVs and target drones;[20] auxiliary power units and environmental control systems for aircraft and helicopters along with all the connected manufacturing processes including precision casting, hi-tech machining of metals and subsequent assembly of finished products.[21]

Apart from aviation equipment, PBS VB offers products and services in areas of precision casting (turbine wheels, turbine blades, spinner disks for insulation wool and femoral components),[22] cryogenic technology (helium expansion turbines, compressors and pumps)[23] and electroplating services.

Aerospace products

Turbojet jet engines

- PBS TJ40-G1[24] – max thrust: 395 N, outer diameter: 147 mm, length: 304 mm, weight: 3.3 kg

- PBS TJ40-G2 – max thrust: 395 N, outer diameter: 147 mm, length: 373 mm, weight: 3.8 kg

- PBS TJ80-120[25] – max thrust: 1,200 N, outer diameter: 235 mm, length: 514 mm, weight: 12,8 kg

- PBS TJ100[26] – max thrust: 1,300 N, outer diameter: 272 mm, length: 625 mm, weight: 19.5 kg

- PBS TJ150[27] – max thrust: 1,500 N, outer diameter: 272 mm, length: 520 mm, weight: 19.6 kg

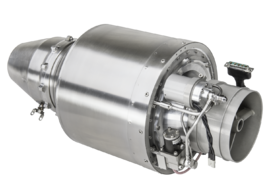

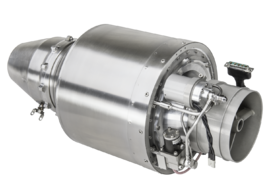

PBS TJ80

PBS TJ80- PBS TJ100

Turboprop engines

- PBS TP100 – Max. power: 180 kW, electrical power output: 720 W, length: 891 mm, weight: 61.6 kg

Turboshaft engines

- PBS TS100ZA – Max. power: 180 kW, 5978 rpm, electrical power output: 720 W, length: 829 mm, weight: 56.7 kg

- PBS TS100DA – Max. power: 180 kW, 2158 rpm, electrical power output: 720 W, length: 881 mm, weight: 61.3 kg[28]

Auxiliary power units

- SAFIR 5K/G MI – power supply: 3x 115 V/200 V/ 400 Hz, max. bleed air: 28.3 kg/min, max. altitude: 6,000 m, weight: 64 kg. The unit is designed to deliver compressed air for starting the main engines and to supply AC to the deck network of medium heavy helicopters.

- SAFIR 5K/G MIS – power supply: 28 V DC, max. bleed air: 28.3 kg/min, max. altitude: 6,000 m, weight: 57 kg. The unit is designed to deliver compressed air for starting the main engines and to supply AC to the deck network of medium heavy helicopters.

- SAFIR 5L – max. bleed air: 32 kg/min, max. altitude: 8,000 m, weight: 42 kg. The unit is designed to supply compressed air for starting the main engines of subsonic light aircraft.

- SAFIR 5K/G Z8 – power supply: 3x 115 V/200 V/ 400 Hz, max. altitude: 6,000 m, weight: 48.5 kg. The unit is designed to supply AC for starting the main engines, as well as to the deck network of medium heavy helicopter.

Environmental control systems

All systems are designed for air-conditioning and ventilation of the main cockpit and other parts of the machine.[29]

Metallurgy and precision casting

PBS VB produces wheels, blades and components made predominantly from IN 713C, IN 713LC and MarM247, i.e. nickel and cobalt-based alloys:[30]

Turbine wheels (weight: 0.15 – 44 kg, dimensions: ø50 - ø400 mm).

Turbine blades and gas turbine segments (weight: 0.1 – 30 kg, length: 50 – 400 mm).

Spinner discs for the production of glass wool-based insulation made from nickel-based superalloys 141I or 2.4879, or of Co alloys. Alloy 141I is a developed directly in PBS for the spinners with long life durability.[31]

Femoral components (10 various types of cobalt-based knee replacements).[32]

References

- "Czech Business Register".

- "Regional Online Magazine: #brnoregion".

- "Czech Business Register".

- "Czech Business Register".

- "PBS Aerospace, inc. official website".

- "Czech Business Register".

- 55 let První brněnské strojírny ve Velké Bíteši (in Czech and English). Jiří Jeřábek. 2005. ISBN 80-254-3181-9.

- "Aero Signed L-59 Overhauls Contracts". www.defense-aerospace.com. Retrieved 2020-03-03.

- Czech Trade Promotion Agency. "Czech Aviation Catalogue - online version" (PDF).

- "The Czech aviation industry has good times ahead, Milan Macholán, director of PBS Velká Bíteš says (part II) | Czech Defence Journal". www.czdjournal.com (in Czech). Retrieved 2020-03-03.

- Editor (2019-02-20). "Czech Turbine Propulsion Supplier PBS Enters Indian Market with Propulsion Units for Unmanned Aircraft". Raksha-Anirveda. Retrieved 2020-03-03.

{{cite web}}:|last=has generic name (help) - "EASA Certificate - available online" (PDF).

- "DOA Certificate - available online" (PDF).

- "POA Certificate - available online" (PDF).

- "MOA Certificate - available online" (PDF).

- "ISO Certificate - available online" (PDF).

- "ISO Certificate - available online" (PDF).

- "Asociace obranného a bezpečnostního průmyslu ČR – Member detail". Retrieved 2020-03-03.

- "Asociace leteckých výrobců". www.alv-cr.cz. Retrieved 2020-03-03.

- "The Czech aviation industry has good times ahead, Milan Macholán, director of PBS Velká Bíteš says (part I) | Czech Defence Journal". www.czdjournal.com (in Czech). Retrieved 2020-03-03.

- "Aiming high". Industry Europe. 2018-03-29. Retrieved 2020-03-03.

- "PBS – Top European Investment Casting Foundry". www.foundry-planet.com (in German). 2020-01-13. Retrieved 2020-03-03.

- Haruyama, T.; Mitsui, T.; Yamafuji, K. (1997-04-01). Proceedings of the Sixteenth International Cryogenic Engineering Conference/International Cryogenic Materials Conference. Elsevier. ISBN 978-0-08-053975-1.

- "PBS TJ-40". Minijets. Retrieved 2020-03-03.

- "Aeromag". www.aeromag.in. Retrieved 2020-03-03.

- "Jet in a Box". www.aopa.org. 2012-05-12. Retrieved 2020-03-03.

- "PBS Velká Bíteš TJ150 turbojet engine delivers 150kg thrust in under 20kg". FINN - The Aviation Industry Hub | FINN. 2019-09-11. Retrieved 2020-03-03.

- "Aeromag". www.aeromag.in. Retrieved 2020-03-03.

- "Environmental Control Systems of Airplanes and Helicopters". Czech Aerospace Proceedings. 1/2007.

- "PBS – Top European Investment Casting Foundry". www.foundry-planet.com. 2020-01-13. Retrieved 2020-03-03.

- "Comparison of Mechanical Properties and Fracture Behaviour of Co-Base and Ni-Base Alloys - available online" (PDF).

- "Femoral Components Market New Research Study Report with Size, Share, Trends, Emerging Applications, Opportunities and Worldwide Analysis with Regional Analysis 2019 to 2025". MarketWatch. Retrieved 2020-03-03.

External links

Другой контент может иметь иную лицензию. Перед использованием материалов сайта WikiSort.org внимательно изучите правила лицензирования конкретных элементов наполнения сайта.

WikiSort.org - проект по пересортировке и дополнению контента Википедии