avia.wikisort.org - Manufacturer

Safran Aircraft Engines, previously Snecma (Société nationale d'études et de construction de moteurs d'aviation) or Snecma Moteurs, is a French aerospace engine manufacturer headquartered in Courcouronnes and a subsidiary of Safran. It designs, manufactures and maintains engines for commercial and military aircraft as well as rocket engines for launch vehicles and satellites.

| |

| Type | Subsidiary |

|---|---|

| Industry | Aerospace Defence |

| Founded | 1945 |

| Headquarters | , France |

Key people | Olivier Andriès (CEO) |

| Products | Aircraft engines Rocket engines |

| Revenue | |

Net income | |

Number of employees | 15,700 (2016) |

| Parent | Safran |

| Website | www |

Some of its notable developments, alone or in partnership, include the Dassault Rafale's M88 engine, the Concorde's Olympus 593, the CFM56/CFM-LEAP for single-aisle airliners, and the Ariane 5's Vulcain engine.

The company employs around 15,700 people across 35 production sites, offices, and MRO facilities worldwide and files an average of nearly 500 patents each year.

Safran Aircraft Engines also notably operates two joint ventures with GE Aviation: CFM International, the world’s leading supplier of commercial aircraft engines,[2] and CFM Materials.

Timeline

- 1945: Snecma was formed when the French aircraft engine manufacturer Gnome & Rhône was nationalised. The name 'Snecma' was an acronym for Société nationale d'études et de construction de moteurs d'aviation (in English: 'National Company for the Research and Construction of Aviation Engines').

1946: Initial employees were German engineers, primarily from BMW, located in Decize, France. Group was known as Groupe "O" until 1950. First design product was the ATAR engine.

- 1946 or 1947, the nationalized Établissments Regnier Motor Company was absorbed into Snecma and continued to produce the SNECMA Régnier 4L.

- 1961: Snecma and Bristol Siddeley formed a joint venture to produce a high-performance jet engine for the Concorde. The main body of the engine came from the Bristol Olympus, which was further improved with several refinements including the addition of the variable intakes necessary for supersonic flight.

- 1968: Snecma acquired Hispano-Suiza, Socata and Bugatti.

- 1970: Messier and Snecma agreed to merge their landing gear business. The following year, Messier-Hispano was formed, which was fully acquired by Snecma in 1973. Snecma's landing gear business was further consolidated by the creation of Messier-Hispano-Bugatti (later renamed Messier-Bugatti) in 1977.

- 1974: Snecma and General Electric (GE) created a joint venture named CFM International, beginning a long term cooperation to produce the CFM56 series of turbofan engines.

- 1990: Snecma announced its partnership with General Electric to build and produce the General Electric GE90 engine.

- 1994: Messier-Dowty was formed following the merger of the landing gear businesses of Snecma (Messier) and the British TI Group (Dowty).

- 1997: Snecma fully acquired the Société européenne de propulsion.[3]

- 1998: Snecma took full control of Messier-Dowty.[4]

- 1999: Snecma Services was created to consolidate all maintenance, repair and overhaul (MRO) operations (including Sochata-Snecma).

- 2000: Snecma acquired Labinal, along with its Turbomeca and Microturbo subsidiaries.

- 2001: Hurel-Hispano (now renamed and known as Safran Nacelles) was created to consolidate the group's engine nacelle and thrust reverser business.

- 2005: Snecma merged with Sagem to form Safran. Snecma was divided into two divisions of the new group (propulsion and equipment).

- 2010: Snecma and GE formed CFM Materials as a 50/50 joint venture.

- 2016: Snecma was renamed Safran Aircraft Engines as the main subsidiary of Safran.

Major programmes

In terms of volume, the most impactful commercial aero engine produced by Safran Aircraft Engines is the CFM International CFM56 turbofan powerplant. This engine is both developed and manufactured via a 50-50 joint venture company, CFM International, which Safran jointly owns with the American industrial conglomerate General Electric (GE). Established during the 1970s, the CFM56 was not an early success; by April 1979, the joint venture had not received a single order in five years and was allegedly two weeks away from being dissolved.[5] The program was saved when Delta Air Lines, United Airlines, and Flying Tigers chose the CFM56 to re-engine their DC-8s; shortly thereafter, it was also selected to re-engine the KC-135 Stratotanker fleet of the United States Air Force, this operator being the engine's biggest customer.[5] Following this turn of fortune, tens of thousands of engines have since been produced over the decades. A total of 30,000 CFM56s have been completed by July 2016.[5]

Safran Aircraft Engines is also the main partner for several other engines coproduced with GE, including the CF6-80 and GE90.[6][7] Safran Aircraft Engines is also involved in the Engine Alliance, which manufactures the GP7000 high-thrust turbofan engine, one of the only two powerplants certified to power the twin-decker Airbus A380.[8][9] During the 2010s, Safran started manufacturing its portion of the LEAP engine via the CFM International joint venture; Safran and GE each assemble half of the annual volume.[10] To cope with high demand for the LEAP engine, CFM has duplicated supply sources for 80% of parts and as well as subdivided assembly sites.[11]

Safran Aircraft Engines is also involved in PowerJet, a joint venture business with Russian aero engine specialist NPO Saturn; this company produces SaM146 turbofan engine, which is used to power the Sukhoi Superjet 100 regional jet.[12] During 2005, a new production plant was founded in Rybinsk, VolgAero, to manufacture components of the SaM146; additionally, parts and assemblies of other engines produced by PowerJet's two parent companies are also produced on this site.[13]

In terms of military engines, Safran Aircraft Engines produces the Snecma M88 turbofan. This engine was developed to power the Dassault Rafale fighter aircraft.[14] It fulfills numerous stringent performance criteria, including a high thrust-to-weight ratio, low fuel consumption across all flight regimes, and a long engine life.[15] Additional considerations were afforded to both the M88's maintainability and upgrade potential (73 kN to 105 kN using the same core).[16][17][18] Qualification of the M88-2 engine was completed during 1996 while the first production engine was delivered by the end of that year. It is of a modular design for ease of construction and maintenance, as well as to enable older engines to be retrofitted with improved subsections upon availability, such as existing M88-2s being upgraded to M88-4E standard.[19] In May 2010, a Rafale flew for the first time with the M88-4E engine, an upgraded variant with greater thrust and lower maintenance requirements than the preceding M88-2.[20]

In 2002, the Europrop International (EPI) consortium was set up by four aero engine manufacturers, Safran Aircraft Engines, Germany's MTU Aero Engines, Britain's Rolls-Royce Holdings and Spain's Industria de Turbo Propulsores.[21][22][23] EPI GmbH is tasked with designing, developing, marketing, manufacturing and providing support for the TP400-D6 turboprop engine to power the Airbus A400M Atlas, a military airlifter manufactured by Airbus Defence and Space.[24][25][23][26] The TP400 is the most powerful turboprop in the world currently in production.[27][28]

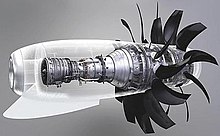

During 2008, the European Commission launched an open rotor demonstration led by Safran within the Clean Sky program with 65 million euros funding over eight years : a demonstrator was assembled in 2015, and ground tested in May 2017 on its open-air test rig in Istres, aiming to reduce fuel consumption and associated CO2 emissions by 30% compared with current CFM56 turbofans.[29] With its 30:1 bypass ratio, it should deliver a 15% improvement over the CFM International LEAP already at 11:1; but Airbus is more interested in the more conventional Ultra High Bypass Ratio (UHBR) turbofan at 15:1, which could be introduced from 2025, offering 5% to 10% better efficiency than the LEAP and to be tested from 2020.[30] Built around the M88's core, the fan blades are slower than the 1980s GE36 due to the reduction gear, lowering noise and the fan can be mounted at the engine front for under-wing configurations.[31] The gearbox and the blade variable-pitch technologies were validated in 100 cycles and 70 hours of tests, including 25% at takeoff thrusts of 21,000–25,000 lbf (93–111 kN), reverse thrust, and rotor imbalance with a blade weight. Afterwards, it was disassembled in April 2018 to examine each part and refine expected wear predictions. GE Aviation was involved through its Italian subsidiary Avio Aero, providing the gearbox and the low-pressure turbine. To be certified, a blade-out event have to be extremely improbable, less than once every billion flight hours as its RTM carbon fiber fan blades will be supported by the in-service LEAP experience.[32]

During December 2019, Safran and MTU announced an agreement to found a 50/50 joint venture to manage the development, production, and after-sales support activities of the new military aero engine intended to power the Future Combat Air System.[33]

In June 2021, Safran presented an updated architecture for its RISE open rotor concept, with a single to 144-156 in (365-396 cm) fan with variable pitch blades forward of a row of static guide vanes, to deliver 30,000lb of thrust (133 kN) with 20% better efficiency than the CFM LEAP.[34]

Products

Aircraft

- SNECMA Coleoptere

Commercial engines

- CFM International CFM56 (50%)

- CFM International LEAP (50%)

- PowerJet SaM146 (50%)

- General Electric GE90 (23.5%)

- General Electric CF6 (10–20% share of production, depending on engine model)

- Engine Alliance GP7000 (10%)

- Safran Silvercrest (under development)

- 5,000 shp turboprop (under study) for 70–90 seater regional airliners[35][36]

Military engines

- SNECMA Atar

- SNECMA M53

- SNECMA M88

- EuroProp TP400-D6 (28%)

- SNECMA Turbomeca Larzac

Space engines

- Viking

- HM7B

- PPS-1350

- PPS-5000

- Vinci (under development)

- Vulcain

Sites

- Courcouronnes: Headquarters

- Évry-Corbeil

- Gennevilliers

- Istres

- Guiana Space Centre

- Le Creusot

- Vernon

- Melun Villaroche Aerodrome

- Saint-Quentin-en-Yvelines

- Châtellerault

References

Citations

- "Preliminary Results 2018". Safran. Retrieved 30 December 2019.

- "• Global aircraft engine market share by manufacturer | Statista".

- "Societe Europeenne De Propulsion (France)". Jane's Space Systems and Industry. 12 April 2005. Retrieved 18 March 2009.

- "Snecma lands in full control of Messier-Dowty as TI sells out". Flight Global. 17 December 1997. Retrieved 30 December 2019.

- "30,000th CFM56 engine comes off the production-line" (Press release). CFM international. 12 July 2016.

- "First Year in Service for GE90 a Huge Success" (Press release). GE Aviation. 18 November 1996.

- "commercial aircraft engines -GE90" (PDF). Snecma. Safran.

- "Engine Alliance, LLC: Private Company Information". Bloomberg. Retrieved 24 June 2016.

- About Us | Engine Alliance Archived 14 March 2012 at the Wayback Machine

- "CFM confirms initial LEAP-1A and LEAP-1B assembly allocation". MRO Network. 15 December 2016. Retrieved 24 December 2017.

- "New GE plant highlights CFM ramp-up strategy on Leap". Flight Global. 16 November 2016.

- Kaminski-Morrow, David (23 June 2010). "EASA certifies PowerJet SaM146 for Superjet". Flight Global.

- Fitzsimons, Bernard (25 July 2007). "Sum of Superjet's parts more than an airplane". AINonline.

- Flight International 1983, p. 1,294.

- Williams 2002, pp. 92, 96.

- Williams 2002, p. 96.

- Moxon 1996, p. 26.

- Norris and Sedbon 1991, p. 35.

- "Snecma M88". Flightglobal. 9 June 1999. Archived from the original on 20 October 2013. Retrieved 12 January 2013.

- "Rafale Fighter Flies with Upgraded M88-4E Engine". Defense Talk. 7 May 2010. Archived from the original on 12 October 2013. Retrieved 15 January 2013.

- "EUROPROP INTERNATIONAL". Safran Aircraft Engines. 1 April 2015. Retrieved 18 July 2019.

- "TP400-D6 - MTU Aero Engines". www.mtu.de. Retrieved 18 July 2019.

- "TP400-D6". www.rolls-royce.com. Retrieved 18 July 2019.

- "TP400-D6 - MTU Aero Engines". www.mtu.de. Retrieved 18 July 2019.

- "TP400-D6 - MTU Aero Engines". www.mtu.de. Retrieved 18 July 2019.

- "EPI achieves the assembly of the 400th TP400 turboprop". Safran Aircraft Engines. 18 July 2018. Retrieved 18 July 2019.

- "TP400-D6 turboprop engine - Europrop International". Europrop. Retrieved 18 July 2019.

- "TP400". Safran Aircraft Engines. 22 May 2015. Retrieved 18 July 2019.

- "Safran celebrates successful start of Open Rotor demonstrator tests on new open-air test rig in southern France" (Press release). Safran. 3 October 2017.

- Guillaume Lecompte-Boinet (4 October 2017). "Safran Inaugurates Open-rotor Test Program". AIN.

- Antony Angrand (10 May 2019). "Safran ponders open rotor options". Air & Cosmos International. pp. 22–23.

- Dubois, Thierry (5 April 2018). "Safran Says Counter-Rotating Open Rotor Engine Relevant". Aviation Week & Space Technology.

- "Janes | Latest defence and security news". Janes. 3 December 2019.

- Dominic Perry (14 June 2021). "CFM launches open rotor demonstrator, promising 20% better fuel burn for mid-2030s applications". FlightGlobal.

- "Safran Reveals New Turboprop Efforts". Aviation Week. 1 May 2013. Retrieved 4 August 2013.

- "Safran veut s'attaquer au monopole de Pratt & Whitney" (in French). aerobuzz.fr. 24 January 2012. Archived from the original on 6 August 2013. Retrieved 4 August 2013.

Bibliography

- Gunston, Bill (2006). World Encyclopedia of Aero Engines, 5th Edition. Phoenix Mill, Gloucestershire, England, UK: Sutton Publishing Limited. ISBN 0-7509-4479-X.

- "Snecma develops M88". Flight International. Surrey, UK: IPC Transport Press. 124 (3888): 1,294. 6–12 November 1983. ISSN 0015-3710. Archived from the original on 18 October 2014.

- Moxon, Julian (16–22 March 1986). "Snecma advances M88 demonstrator". Flight International. Surrey, UK: IPC Transport Press. 129 (4003): 26. ISSN 0015-3710. Archived from the original on 18 October 2014. Retrieved 14 May 2017.

- Norris, Guy; Sedbon, Gilbert (10–16 April 1991). "Power to Progress". Flight International. London, UK: Reed Business Information. 139 (4262): 32–36. ISSN 0015-3710. Archived from the original on 13 January 2010.

- Williams, Mel, ed. (2002). "Dassault Rafale". Superfighters, The Next Generation of Combat Aircraft. London: AIRtime Publishing. ISBN 978-1-880588-53-6.

External links

На других языках

[de] Safran Aircraft Engines

Safran Aircraft Engines (bis 2015: Snecma[2]) ist der führende französische Hersteller von Flugzeugtriebwerken und von Raketenmotoren für die Raumfahrt. Das Produktportfolio reicht von kleinen Kolbenmotoren über Strahltriebwerke bis zu Booster-Triebwerken für Ariane-Raketen. Das in Courcouronnes in Frankreich ansässige Unternehmen bedient dabei sowohl den zivilen als auch militärischen Markt. Im Geschäftsjahr 2016 erwirtschaftete es mit rund 15.700 Mitarbeitern einen Umsatz von etwa 8 Milliarden Euro. Safran Aircraft Engines ist ein Tochterunternehmen von Safran S.A.- [en] Safran Aircraft Engines

[es] Safran Aircraft Engines

Safran Aircraft Engines (antes Snecma,siglas en francés de Société Nationale d'Étude et de Construction de Moteurs d'Avion) es un fabricante francés de motores aeroespaciales, que desarrolla, fabrica y comercializa, solo o en cooperación, motores de reacción para aeronaves civiles y militares, vehículos de lanzamiento y satélites. Snecma también ofrece a las líneas aéreas, y operadores de aeronaves militares una gama completa de servicios para sus motores de aviación.[1][fr] Safran Aircraft Engines

Safran Aircraft Engines, anciennement Société nationale d'étude et de construction de moteurs d'aviation puis Snecma, est une société française du groupe Safran, spécialisée dans l'étude et la fabrication de moteurs pour l'industrie aéronautique et spatiale. Motoriste de premier rang, Safran Aircraft Engines conçoit, développe, produit et commercialise, seul ou en coopération, des moteurs pour avions civils et militaires, pour lanceurs spatiaux et satellites. Safran Aircraft Engines équipe l'ensemble des avions de chasse français comme le Rafale avec son moteur M88 ou le Mirage 2000 avec son moteur M53. Avec General Electric, Safran Aircraft Engines a créé la coentreprise CFM International qui motorise aussi bien les avions Airbus que les avions Boeing.[it] Safran Aircraft Engines

SNECMA è un'azienda francese leader nel mondo nel settore aerospaziale, specializzata nella fabbricazione di motori per l'industria aeronautica e aerospaziale. L'acronimo SNECMA stava per Société Nationale d'Étude et de Construction de Moteurs d'Aviation fino al 2005, quando l'azienda si è fusa con Sagem per formare SAFRAN.[ru] Snecma

Snecma (акроним от Société Nationale d'Étude et de Construction de Moteurs d’Avions — Национальное общество по разработке и конструированию авиационных моторов) — французская компания, один из мировых лидеров среди аэрокосмических корпораций по разработке и производству авиационных двигателей. В 2005 году объединилась с компанией SAGEM, образовав холдинг SAFRAN (является подразделением группы SAFRAN).Другой контент может иметь иную лицензию. Перед использованием материалов сайта WikiSort.org внимательно изучите правила лицензирования конкретных элементов наполнения сайта.

WikiSort.org - проект по пересортировке и дополнению контента Википедии